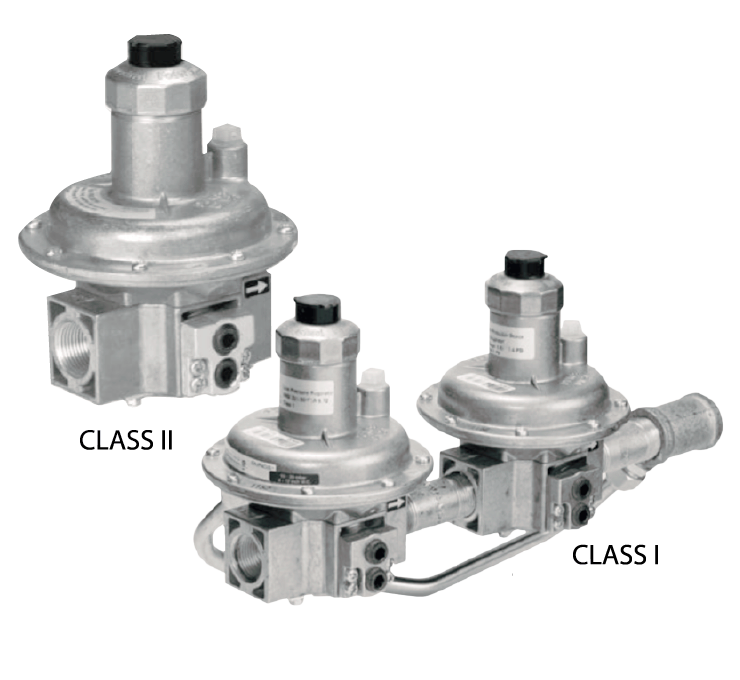

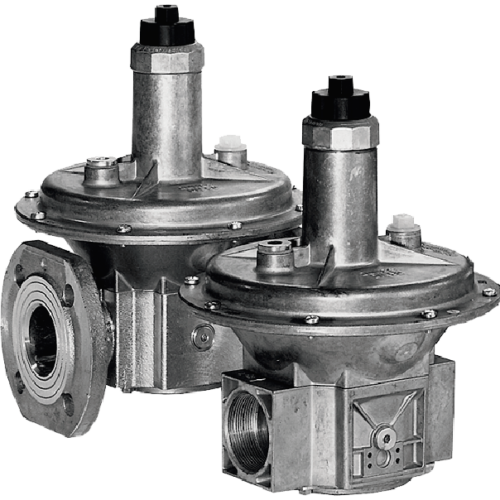

Descripción

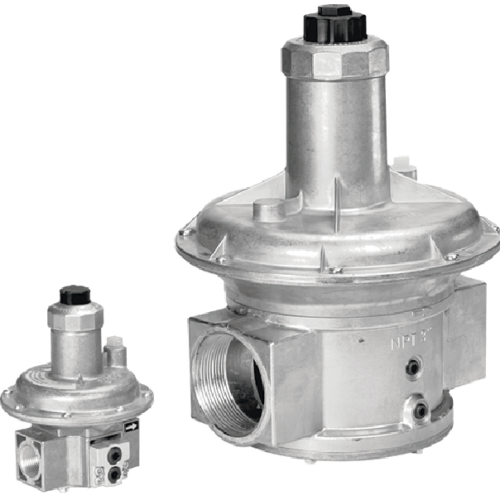

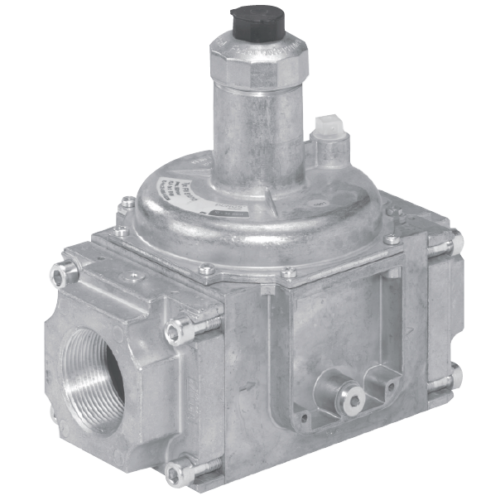

El FRS-Regulador de Presión Dungs – Serie 700/6 Roscada are a balancing type, spring-loaded regulator with an adjustable setpoint. They feature an internal sensor for regulating output pressure.

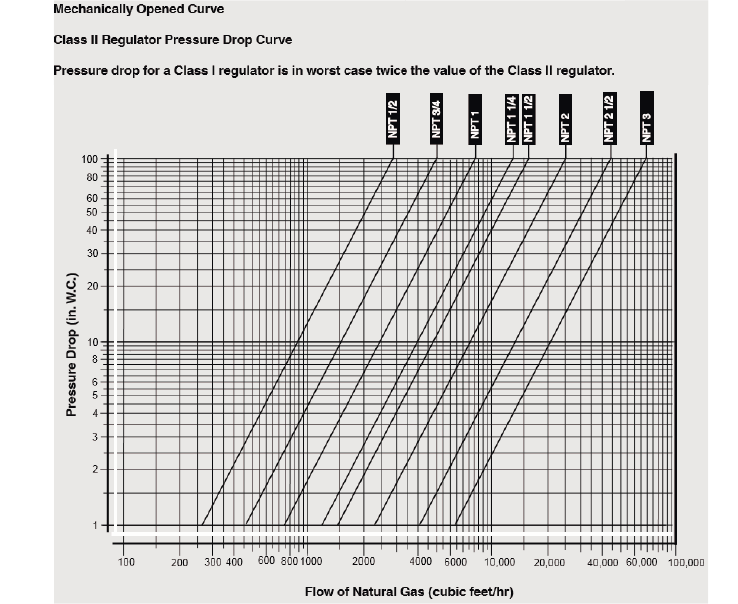

- Input pressures up to 10 PSI (See specifications for more details) and NPT 1/2” to NPT 3” thread connections (FRS 7../6)

- Heavy duty diaphragm construction for durability and strength.

- Steady, precise and instantaneous regulation of the outlet pressure.

- Lock-up type regulator (see page 2 and 3 for details).

- Factory installed vent limiter. Review applicable codes for vent line requirements.

FRS Spring-loaded pressure regulator with adjustable setpoint spring. Internal/External impulse for regulating output pressure.

Aplicaciones del FRS-Regulador de Presión Dungs – Serie 700/6 Roscada

- The FRS series line pressure regulators are recommended for applications when incoming gas pressure from the service regulator needs to be reduced to a suitable pressure for the gas appliance pressure regulator. These are designed for high efficiency appliances, high-turn down appliances, appliances using direct spark ignition or hot surface ignition, and other applications requiring a high performance regulator.

- The FRS is suitable for dry natural gas, propane, butane, air and inert gases. The FRS does not contain any nonferrous metals and is suitable for gases containing no more than 0.1 % by volume, dry H2S.

- A “dry” gas has a dew point lower than +15 °F and its relative humidity is less than 60 %.

Ficha técnica – Click aquí

Productos Relacionados – ● FRI: Regulador De Presión Dungs – Bridas Por Separado ● FRG- Regulador/Válvula Proporcional Dungs -Roscada ● FRS-Regulador De Presión Dungs – Serie 500/Roscada Y Serie 5000/Bridada

FRS-Regulador de Presión Dungs – Serie 700/6 Roscada de venta aquí, contacta a alguno de nuestros asesores dentro del chat o marca al número de sucursal más cercano a ti, será un placer atenderte.

Valoraciones

No hay valoraciones aún.