Descripción

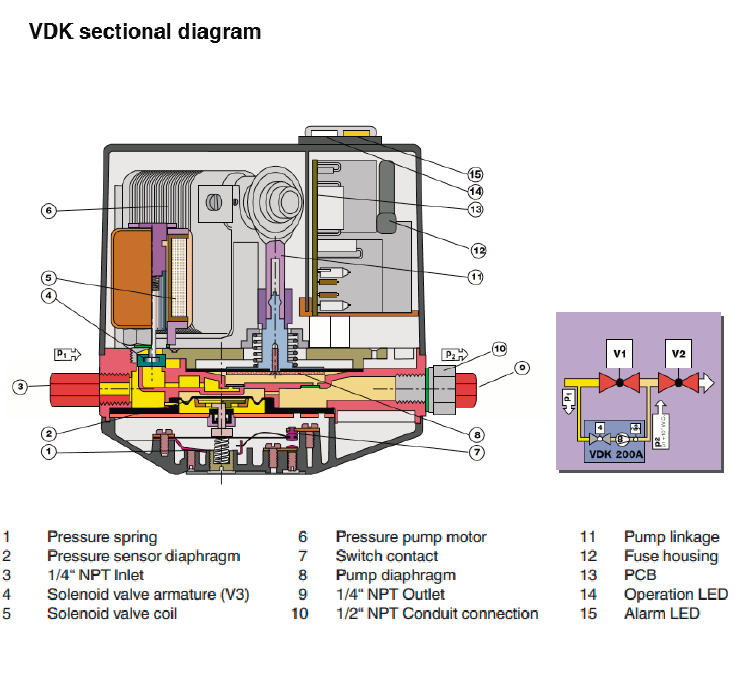

VDK 200 A S06 Dungs: Control de Estanqueidad is a valve proving system for safety shutoff valves. It verifies that both safety shutoff valves in a gas train are fully closed before a system start-up or after system shutdown when wired and interlocked to a suitable flame safeguard control. The VDK will halt the start-up sequence and prevent ignition when the VDK detects an open automatic shutoffn valve or valve leakage exceeding the detection limit (see page 5 for detectionlimits).

- Max. test volume 0.7 ft3

- Release Signal Timing:(approx. 26 s for RUN and 32 s for ALARM)

- “RUN” or “ALARM” indicated by a light.

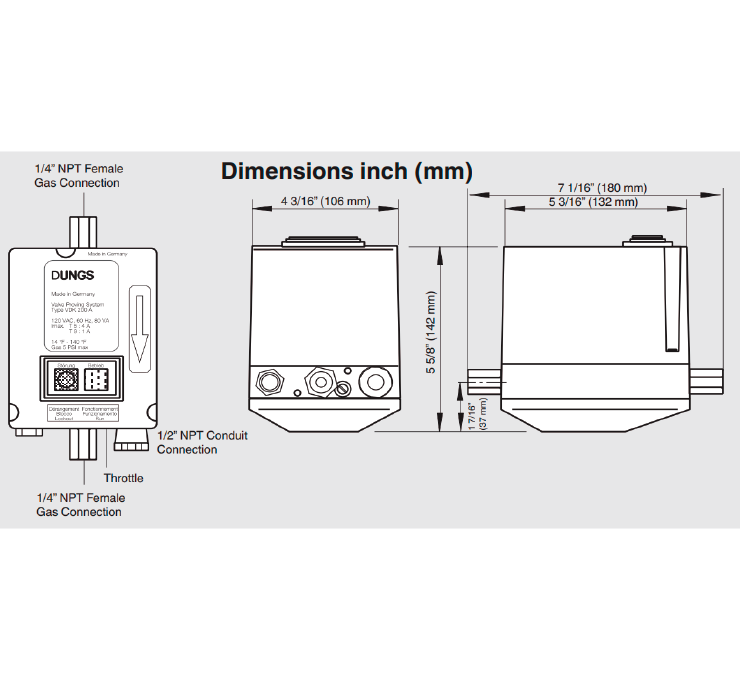

- Electrical connection at screw terminals via 1/2“ NPT conduit connection.

- Detectable leakage rate: < 1.76 ft3/hr

- Field adjustable needle valve to accommodate various pipe volumes.

VDK 200 A S06 Valve proving system for automatic safety shutoff valves.

Aplicaciones VDK 200 A S06 Dungs: Control de Estanqueidad

- The VDK is recommended for industrial and commercial heating applications. Some authorities having jurisdiction accept the VDK in lieu of “proof of closure” when integrated with the preignition system and/or lieu of a vent valve when it checks the valves at start up and shut down. It can also be used as a valve seat tightness check when used within its capabilities.

- – The VDK is suitable for dry natural gas, propane, butane, air and inert gases. Not suitable for hydrogen gas. A “dry” gas has a dew point lower than +15 °F and its relative humidity is less than 60 %.

Ficha técnica– Click aquí

Instrucciones de operación y montaje– Click aquí

Productos Relacionados – ● VPS S06 Dungs: Control De Estanqueidad ● Señalizador De Posición De Válvulas Dungs- Serie K01/1 ● VPS 504 Dungs: Control De Estanqueidad ● Válvula De Prueba Para Manometros – Dungs

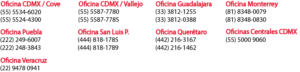

VDK 200 A S06 Dungs: Control de Estanqueidad de venta aquí, contacta a alguno de nuestros asesores dentro del chat o marca al número de sucursal más cercano a ti, será un placer atenderte.

Valoraciones

No hay valoraciones aún.